460 AUTOMATED ROTARY BLADE GRINDER

Advantages & Benefits

The most innovative product to enter the turfcare industry in years! Fully enclosed to keep dust and noise in, and dual grinding heads that result in time savings of up to 70%. Reproduce the OEM grind surface with minimal effort. And the automated infeed and built-in blade balancing system allow for a faster, safer and more consistent blad sharpening process.

While the OEM’s recommend grinding every eight to ten hours of use for maximum engineered performance, the 460 will reduce your labor, will reduce your effort, and provide the best grind possible for your cutting unit investment. More stress on hydraulics, added strain on your engine, and increased fuel consumption is typical when blades are not sharpened regularly.

-

OEM End of Grind Blend Radius

ButtonThe cutting edges of OEM blades feature a blend-out radius to minimize material stresses. That radius can now be replicated with our patent-pending blend radius grinding feature, producing more consistent and safer results.

-

Built-in Blade Balancing System

ButtonThis unique design ensures not only a perfectly-sharpened blade, but also one that's properly balanced - all without any secondary operations.

-

Adjustable Height / Angle

ButtonEnsures clearance with a variety of "airfoil-lift" blade designs. Pivot feature allows for angle adjustments to match OEM grind angle specification.

-

Reliable Centering

ButtonQuickly and securely aligns and positions the blade for precise sharpening

-

Dual Grinding Heads

ButtonBy grinding both cutting edges simultaneously, operators can realize time savings of up to 70%.

-

Proximity Switches

ButtonFast and consistent set-up for identical blades is achieved with durable traverse-proximity switches. The result is a perfect, consistent grind every time.

-

Blend Radius Relief Slide Bar

ButtonThe measuring decal associated with the relief slide bar makes the set-up process extremely fast. This is one of the many features that makes the repeatability of set-up easy, and reduces the amount of time to change from different blade types to mere seconds.

SPECIFICATIONS

- Part #: 4600901

- Power: 115 vac, 50/60 HZ, single phase, 15 AMP

- Weight: 890 pounds (404 kg)

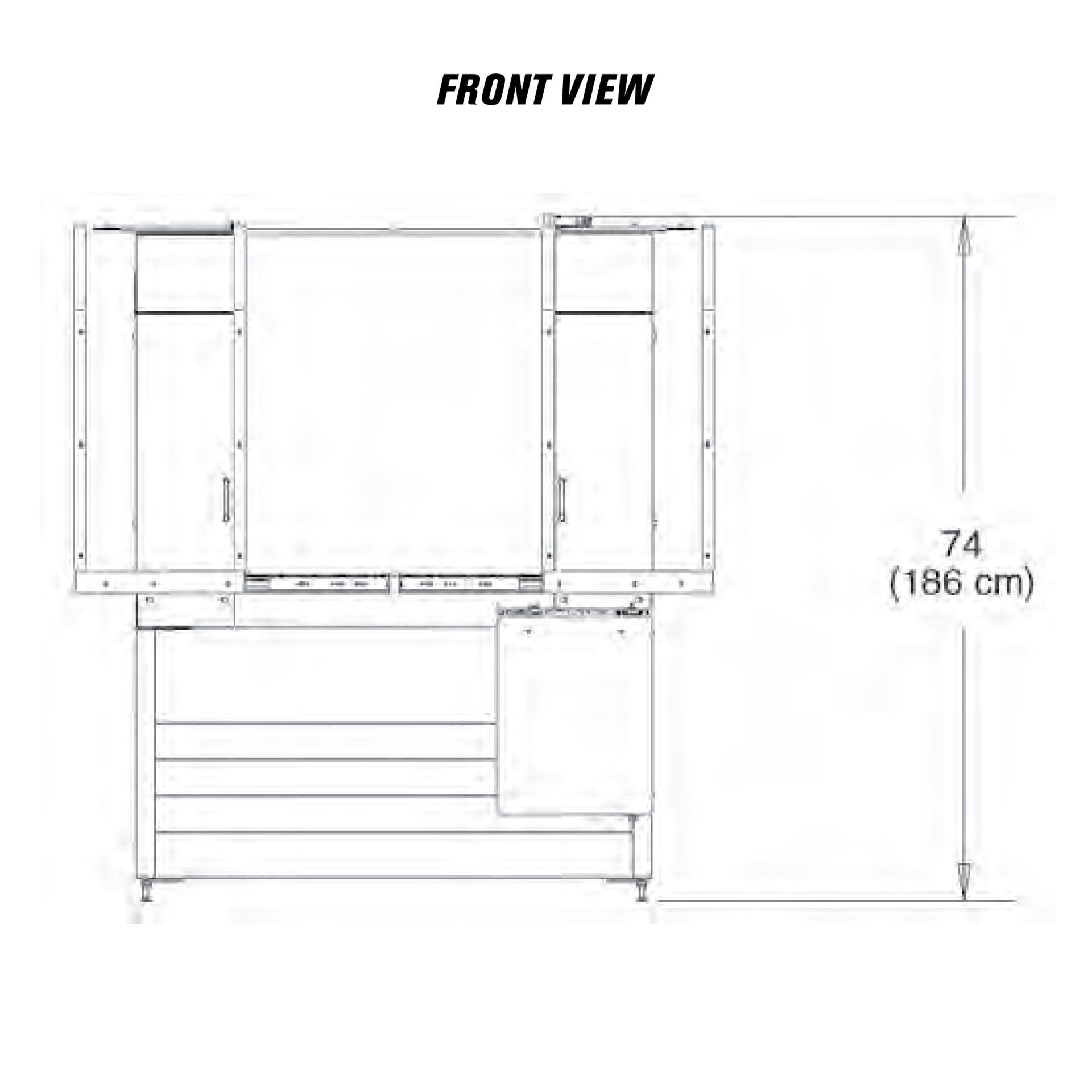

- Height: 74” (188 cm)

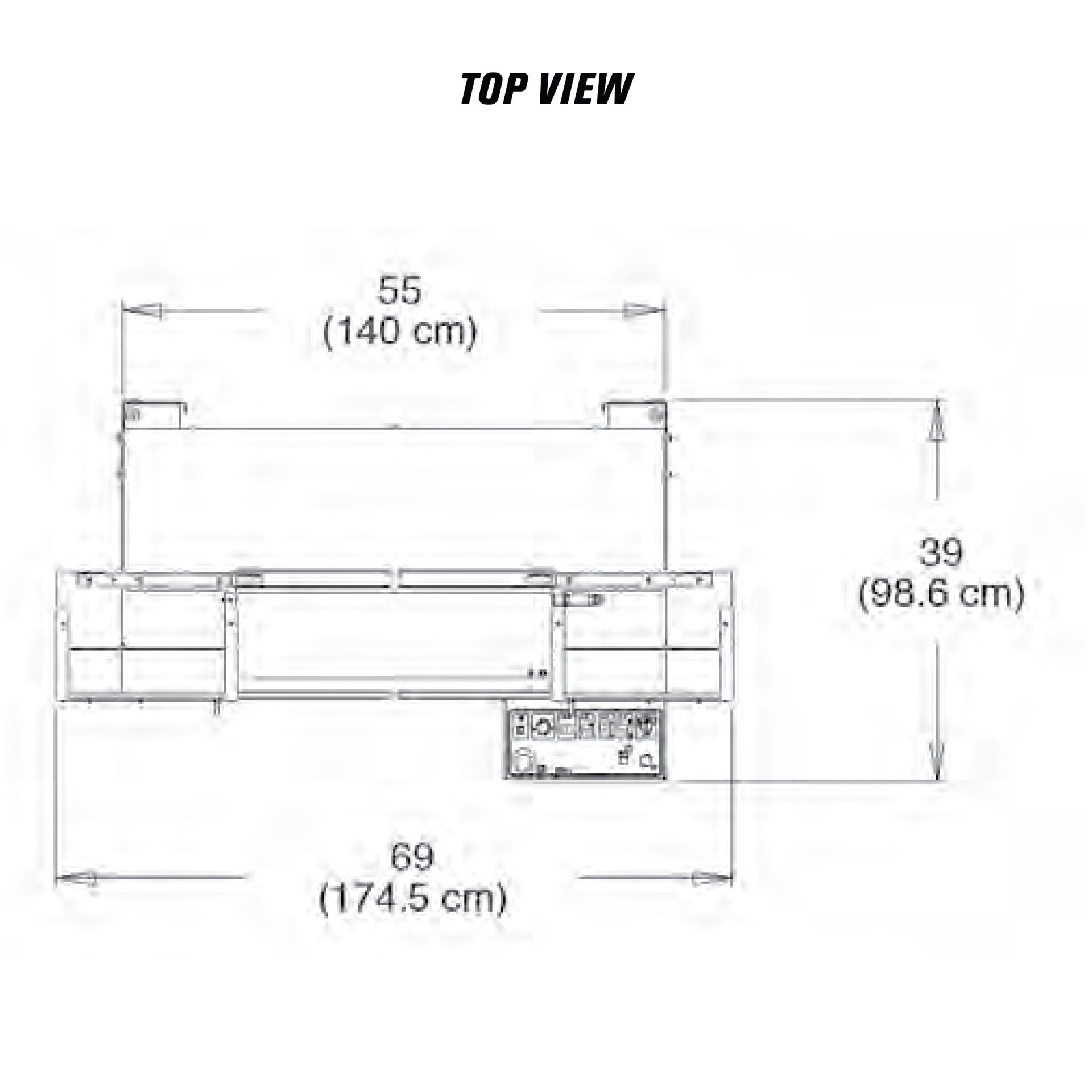

- Width: 56” (142 cm) doors closed, 69” (175 cm) doors open

- Depth: 40” (102 cm) machine only

- Grinding Motors: 1/2 HP TENV, 3450 RPM 50/60 HZ (2)

- Traverse Motor: 1/20 HP DC variable speed gearmotor

- Maximum Rotary Blade Length: 34” (86 cm)

STANDARD FEATURES

- 5” (127 mm) diameter cupped grinding wheels (2)

- Patent pending dual head and relief radius system

- Structurally engineered steel frame

- Safety guarding standard

- Automatic grind control system

DIMENSIONS